Spira brings you the Evolution of Quality

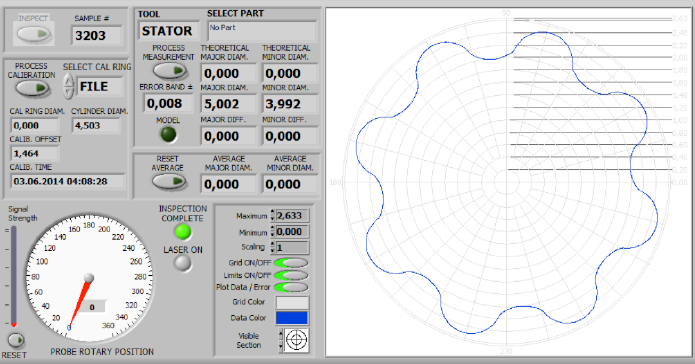

Rotor and stator fit is critical in all power section applications but exceptionally critical when manufacturing uniform wall power sections. Spira Systems measures the full lasered profile of every purchased stator upon customer request as well as 20% of our standard production population.

In addition to profiling the cavity with a laser, we also use the minor diameter rapid check tool for stators. This tool is popular for its speed, cost, and ease of use, however measurements should not be considered absolute due to the influence of hardness and compressed geometry. Selecting fit based on the inferred laser measurement is supported as a best practice to minimize mis-fitting a stator due to poor measurement quality.

Spira Systems also offers the full CMM profile for every rotor manufactured at every step of the manufacturing process.

We also use rapid check rotor measurement tools which have an agreeance within 0.001″ of a CMM measurement. Used rotors can be measured upon request.